Make Best Use Of Worth: Aftermarket Construction Parts Essentials

Make Best Use Of Worth: Aftermarket Construction Parts Essentials

Blog Article

Increase Performance With Costs Aftermarket Building And Construction Components for Heavy Machinery

Benefits of Costs Aftermarket Parts

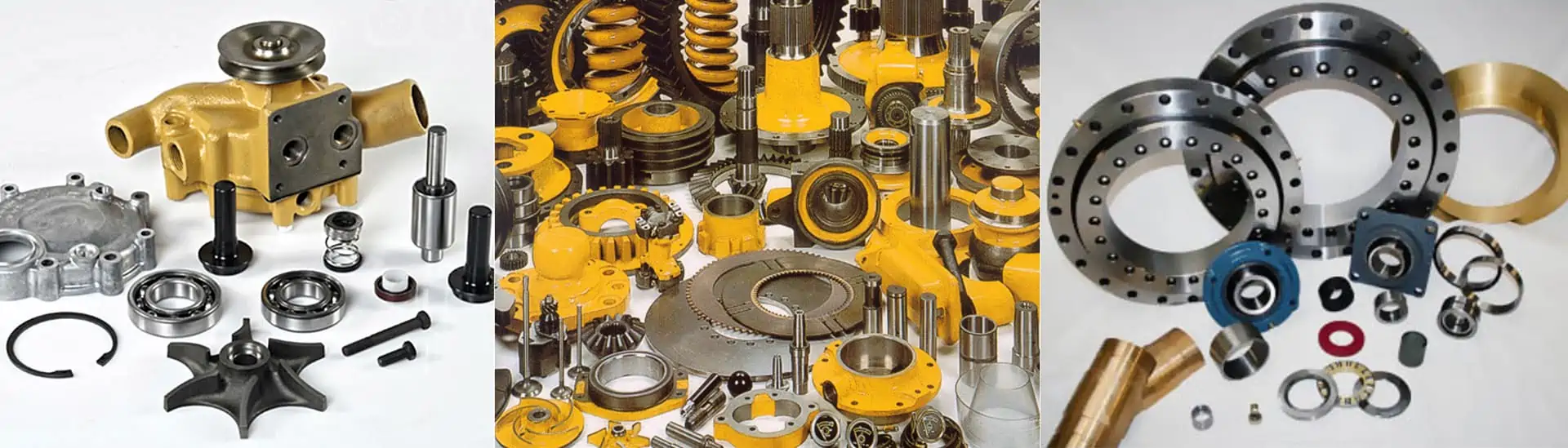

When thinking about heavy equipment maintenance, choosing for premium aftermarket components uses considerable advantages in terms of cost-effectiveness and performance reliability. Premium aftermarket components are created to satisfy or exceed the initial devices supplier (OEM) requirements, ensuring a high level of top quality and compatibility. These components are typically a lot more cost effective than their OEM equivalents, making them a cost-efficient service for businesses wanting to preserve their heavy equipment without endangering on efficiency.

One of the essential benefits of costs aftermarket components is their ability to supply trustworthy performance under demanding conditions. Building and construction sites and commercial settings can be severe settings, putting immense stress on equipment elements. Premium aftermarket components are engineered to withstand these challenges, offering toughness and durability that satisfy the requirements of sturdy procedures. By picking costs aftermarket components, services can reduce downtime, decrease maintenance prices, and guarantee that their machinery operates at peak effectiveness.

Enhancing Machinery Performance

Among the substantial advantages of using premium aftermarket components for hefty equipment upkeep is the improvement they give machinery efficiency popular functional environments. By going with top notch aftermarket components, machinery drivers can experience enhanced performance, efficiency, and general performance of their tools. Costs aftermarket components are especially created to fulfill and even exceed the requirements set by original equipment manufacturers (OEMs), ensuring that hefty machinery runs at peak levels. These parts are engineered with precision and durability in mind, offering boosted dependability and durability to the machinery they are installed in. In addition, premium aftermarket parts can assist enhance gas consumption, reduce downtime for fixings, and decrease the threat of unanticipated break downs, ultimately causing a smoother and a lot more efficient operation of heavy equipment in different construction and commercial settings. Buying premium aftermarket components is a calculated selection for companies seeking to increase the efficiency and long life of their heavy equipment fleet.

Economical Solutions for Upgrades

Carrying out affordable remedies for upgrades in hefty machinery maintenance can considerably affect functional efficiency and overall performance. These aftermarket components go through strenuous testing to ensure they satisfy market criteria and specs, making them a trustworthy choice for machinery upgrades.

Regular maintenance and prompt upgrades can help avoid expensive downtime and extend the life expectancy of hefty machinery. One more economical technique is to invest in modern technology upgrades, such as telematics systems, which can improve devices surveillance and performance optimization - aftermarket construction parts. These systems enable real-time monitoring of machine health metrics, allowing for proactive maintenance and decreasing the danger of unanticipated break downs

Increasing Equipment Long Life

Enhancing the toughness Homepage of heavy equipment is extremely important for maximizing operational performance and minimizing total maintenance costs. Increasing machinery durability involves applying helpful site aggressive actions to expand the life expectancy of equipment. Regular maintenance routines, consisting of oil adjustments, filter substitutes, and evaluations, are important to stop premature wear and determine possible issues prior to they escalate. Using top quality aftermarket parts especially created for heavy equipment can additionally add to lengthening the life expectancy of tools. These parts are typically extra dependable and durable than conventional OEM elements, using raised resilience to extreme working problems. In addition, spending in sophisticated modern technologies such as telematics systems can offer real-time data on maker performance, allowing operators to attend to upkeep needs quickly and successfully. By focusing on equipment durability through a mix of preventive upkeep methods and quality aftermarket components, building business can enhance the efficiency and cost-effectiveness of their procedures while decreasing downtime as a result of unexpected break downs.

Optimizing Equipment Performance

To guarantee the peak efficiency of hefty equipment, optimizing equipment capability is necessary for building and construction firms aiming to make best use of operational performance and lessen downtime. Implementing a preventative upkeep schedule can aid in discovering damaged parts or elements that may hinder the machinery's efficiency.

Including performance tracking systems can aid in reviewing machinery usage patterns and identifying areas for enhancement or adjustment to optimize performance. By focusing on equipment capability optimization, construction firms can enhance performance, extend equipment lifespan, and eventually accomplish greater returns on their heavy machinery financial investments.

Conclusion

When thinking about hefty equipment upkeep, deciding for costs aftermarket parts supplies substantial advantages in terms of cost-effectiveness and efficiency dependability.One of the significant advantages of utilizing costs aftermarket components for heavy equipment maintenance is the improvement they bring to equipment efficiency in demanding functional environments.To make sure the peak performance of heavy equipment, maximizing equipment performance is essential for building and construction firms aiming to make the most of functional effectiveness and reduce downtime. By focusing on machinery performance optimization, building business can improve productivity, prolong machinery life-span, and eventually attain higher returns on their hefty equipment investments.

In final thought, utilizing costs aftermarket building and see page construction components for hefty equipment offers countless advantages, including improved efficiency, economical upgrades, boosted longevity, and optimized functionality.

Report this page